INTRODUCTION

The provisional prosthesis is also called transient or intermediate due to its limited permanence in the mouth while waiting for the permanent prosthesis1; It is designed to assess aesthetics, stability, form and function of the planned final treatment2,3. It is a fundamental procedure in the treatment of fixed prostheses and performs functions such as the protection of pulp tissue against physical, chemical and thermal injuries; maintenance of positional stability, occlusal and aesthetic function that are essential for clinical success1-4.

The provisional restorations can be used for relatively long periods in cases of complete mouth reconstruction or when multiple teeth are prepared so they require a precise marginal adaptation to promote gingival health and protect the prosthetic preparation2,5. Notice that provisional restorations form an integral part of the treatment of fixed prostheses6 as of restorations on implants that allow to define an adequate contour of the tooth and an ideal emergency profile7.

Two factors contribute to form a well-integrated provisional restoration: the optimal marginal adaptation and adequate sealing of the temporary cementing agent to dental structures8. A provisional restoration prepared with poor adaptation induces microfiltration, causing plaque buildup and generating subsequent periodontal problems ranging from gingival inflammation with bleeding to a gingival recession9.

Temporary materials have evolved greatly since its inception, it can be mentioned from the use of acrylics, prefabricated crowns to new resin materials and those generated by computer through CAD / CAM design and manufacturing10,11. This system allows making provisional from industrially polymerized prefabricated blocks, which avoids the heat of polymerization and contraction, presents a good clinical behavior, simplifies steps and allows an adequate marginal adjustment12-14.

The size of the marginal space for a provisional crown should be maintained at approximately 50 to 100um, similar to that of definitive fixed prostheses, in order to provide adequate maintenance of the periodontal and pulp tissues15. Values below 120 um are considered clinically acceptable16; However, other studies show a permitted range of up to 200 um13,17. The marginal adjustment can also be adversely affected by moisture absorption and the thermal cycle that can influence the physical properties of the material. Among other factors such as voids in acrylic resins, polymerization stresses, remaining and unreacted monomer or propagation of thermal stress cracks18.

Due to the clinical importance, it was proposed to determine the marginal adaptation of two materials to make provisional restorations: thermosetting and resin for CAD / CAM, as well as the retention forces that can be provided by two provisional cementing agents of different composition.

Materials and methods

In vitro study. 40 extracted upper premolars were carved to receive a complete crown made with two types of provisional biomaterials (n= 30): a group with Veracril® thermo-curing acrylic (New Stetic, Medellin-Colombia); and, the second group with Temp Basic® resin (Zirkonzahn®, Gais- Italy), with computer-aided design and manufacturing Zirkonzahn® (CAD/CAM). After manufacturing, 10 samples from each group were randomly cemented with Dycal® and Tempbond®. The study was approved by the Subcommittee of Ethics and Research (SEISH) of the Faculty of Dentistry of Central University of Ecuador.

Healthy dental pieces extracted by orthodontic indication were cleaned of soft and hard remains with the use of curettes and ultrasound. It was washed carefully and kept in sterile boxes with physiological solution at 37°C to maintain its hydration. They were placed in self-curing transparent acrylic cubes with the help of a 20 x 20 x 20mm stainless steel.

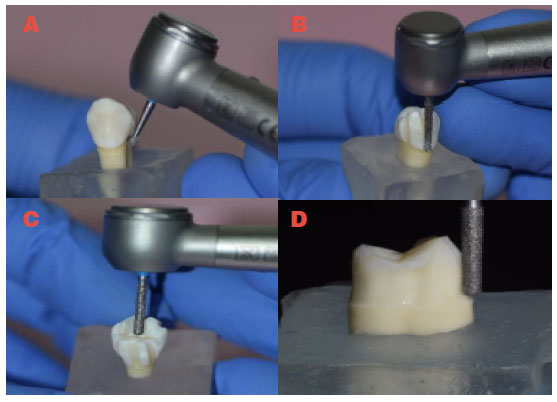

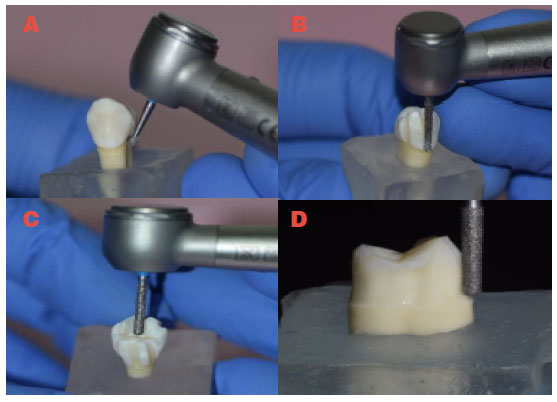

In each sample, a preparation was made for a full crown of porcelain metal; Pegoraro, 200119, the standardization of the samples was carried out through calibration of the dental burs and the change of dental burs every 10 preparations, it began with the marginal cervical groove in the vestibular, palatine and proximal faces using a 1.4 mm spherical diamond drill with a groove depth of 0.7 mm. Orientation grooves were then made in vestibular with a cylindrical cutter with a rounded end of 1.2 mm in diameter, in palatine in its cervical middle third, the grooves obtained a wear of 0.6 mm in depth that corresponded to half the diameter of the cutter and in its mid-occlusal third with a thickness of 1.5 mm and in its occlusal face the grooves were made with a 1.5 mm rounded cylindrical end mill. Then, the orientation grooves were joined with a cylindrical diamond cutter with a rounded end of 1.2mm in diameter, and with a cylindrical cutter with a rounded end of 1.5mm in diameter in occlusal and the middle-occlusal third in palatine. To standardize the cervical-occlusal height of all samples, a height of 4 mm measured was maintained with a periodontal probe from the occlusal groove to the cervical margin. The finishing was done with a truncated conical cutter with a round end and a fine grain of 1.2 mm in diameter and multilaminated or diamond dental burs of extra fine grain, all edges were rounded and a smooth surface was obtained19 (figure 1).

Figure 1. A. Marginal marginal groove. B and C. Vestibular, occlusal and palatal orientation grooves. D. Carved stump. Data base of Investigation

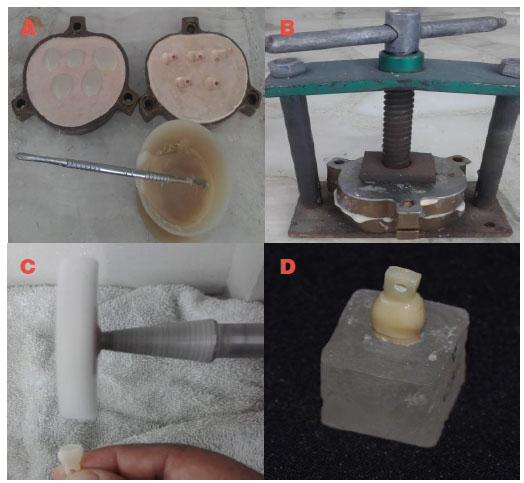

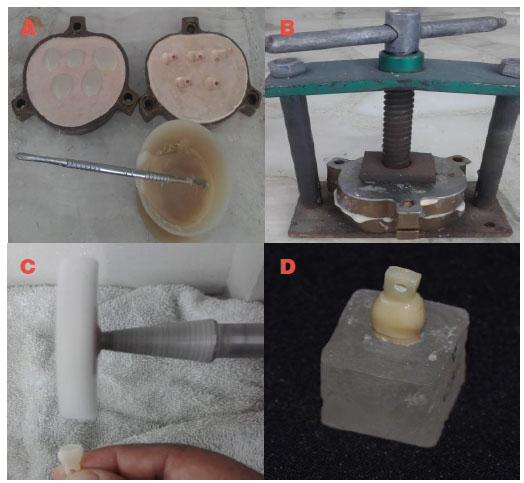

For the thermosetting group, a spacer was placed and waxed with wax (yeti®, USA). Later, the muffling was carried out and then the muffle was placed in boiling hot water with the aim of melting the wax, after this process was removed from the water and opened in order to remove excess wax. The mixture of the acrylic thermosetting resin was carried out according to the instructions of the manufacturer, Veracril® (New Stetic, Medellin-Colombia). The dosage was obtained by weight, two parts of thermopolymerizable polymer powder and one part of liquid monomer, 2: 1 system in all groups to ensure the least dimensional discrepancy of the material. The mixture of powder and liquid was performed in a cross-shaped container continuously for 30 seconds, to avoid the incorporation of air, the container was covered until the mixture reached its plastic stage for handling. Then it was subjected to manual pressing and the surpluses were removed and its polymerization process was continued. The flask was allowed to cool to room temperature, it was opened and the temporary crowns removed. Samples that showed bubbles and irregularities were excluded and those that did not show alterations in their structure were selected. Surpluses were removed and polished using cloth wheel and pumice powder (figure 2).

Figure 2. A. Mixing powder and liquid in a container. B. Manual pressing. C. Polishing of provisional crowns. D. Crown finished. data base of Investigation.

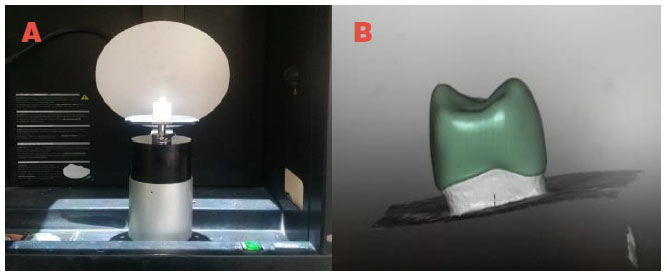

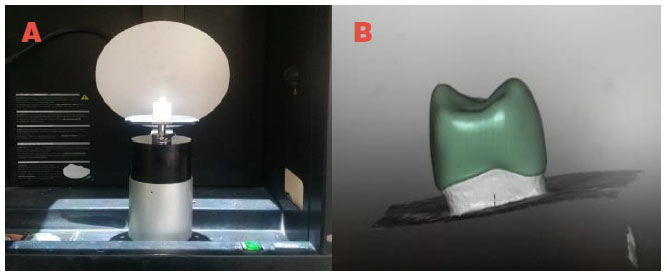

For the CAD / CAM group, a file was created and the encoded data was saved for each sample, then this information was sent to the scanner where the files were prepared. Each of the prepared samples was scanned, the file was sent to a design program (modellier); Subsequently, the design was sent to a program called nestin and a prefabricated Temp Basic® resin disc (Zirkonzahn®, Gais-Italy) was selected. Selected the block and the design of the modellier file, the system made a virtual tour and milling was carried out using the Zirkonzahn® system of each provisional crown for approximately 20 minutes, after the milling was removed from the disk using a fissure mill and preceded polishing with plush milling cutter (figure 3).

Figure 3. A scan of the samples. B. Design of provisional crowns.

After the preparation of the provisional crowns, the temporary cementation in the two groups was randomly followed according to the manufacturer's instructions; for the Dycal® cement, the prepared teeth and the provisional restoration were dried, placed in equal quantities of the base and the catalyst on a paper block and mixed until obtaining a homogeneous color for 10 seconds and placed with a Dycalero in the provisional crown contour and cemented on the preparation with light pressure, we waited its setting time of 3 minutes and the surpluses were removed with an explorer. For the cementation with TempBond NE®, the prepared teeth and the provisional restoration were dried, subsequently placed in equal amounts of the base and the catalyst on a paper block, the mixture was made for 30 seconds to obtain a homogeneous mixture, it was applied in the provisional contour and it was cemented with a slight pressure, we waited its setting time of 7 minutes, then the surplus was removed with an explorer.

In the laboratories of Characterization of Nanomaterials of the University of the Armed Forces (ESPE), the marginal adaptation was observed by means of stereo microscope SZ51 (Olympus, Japan), a millimeter sheet was used as reference, the middle area of the mesial, vestibular faces was measured , distal and palatine obtaining values in µm of the marginal discrepancies for each subgroup that were saved in Excel sheets.

Subsequently, the samples were subjected to an aging process by thermocycling. The thermal cycles submitted were 2,500 cycles equivalent to 3 months of use of the provisional in the mouth, to simulate the changes that occur in the oral cavity5. Each cycle obtained a total time of 90 seconds; 30 seconds in each of the three vessels with different temperatures of 37 °, 5 ° and 55 ° C, completing each cycle. After this process, the samples were placed in saline solution for 24 hours at room temperature and were observed again in the SZ51 stereomicroscope (Olympus, Japan).

Finally, the samples were subjected to tensile forces in the Materials Mechanics laboratories of the University of the Armed Forces (ESPE), using the MTS Universal Testing Machine, model 5002 (MN, USA), at a test speed of 1mm/min until the release of the provisional crowns of the dental stump. The data was stored in Excel tables.

Results

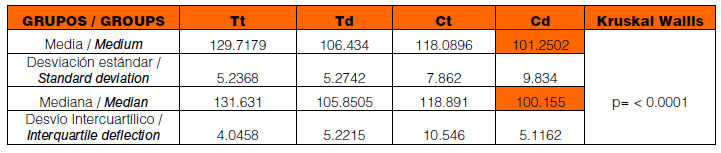

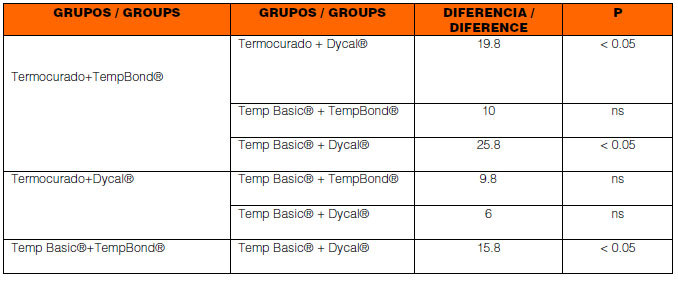

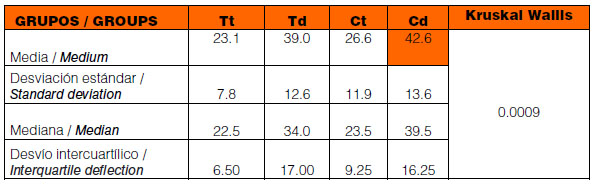

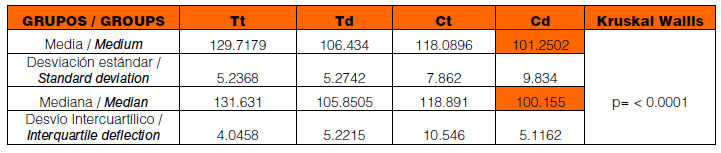

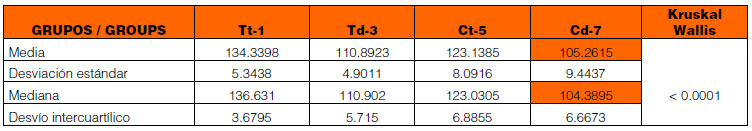

After the cementation process, marginal adaptation was measured and the means and medians of each group were established. The Kruskal-Wallis test determined that there are significant differences between the groups (P = <0.05). (table 1)

Table 1. Medium, median and standard deviation of groups after cementation. Tt: thermo-curing + tempbond; td: thermo-curing + dycal; ct: temp basic + tempbond; cd: temp basic + dycal. Kruskal-wallis p = <0.05.

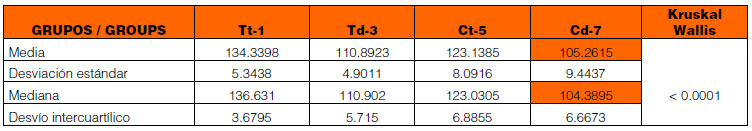

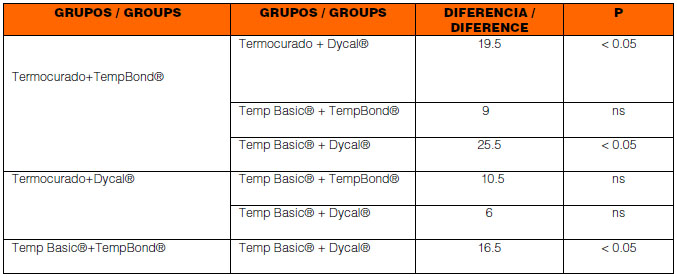

From the Kruskal-Wallis Test, with a level of significance of 95% a value lower than 0.05 was obtained, the alternative hypothesis (Ha) is accepted, that is, there are differences with respect to the central tendency of the populations. It was compared by Dunn's method between groups to establish similarity or difference between them (table 2).

Table 2. Relationship between groups after cementation (Kruskal Wallis - Dunn). Tt: thermo-curing + tempbond; td: thermo-curing + dycal; ct: temp basic + tempbond; cd: temp basic + dycal.

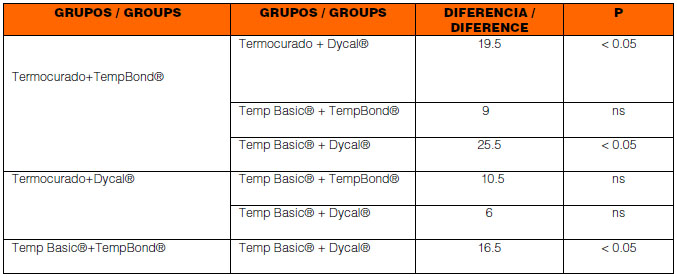

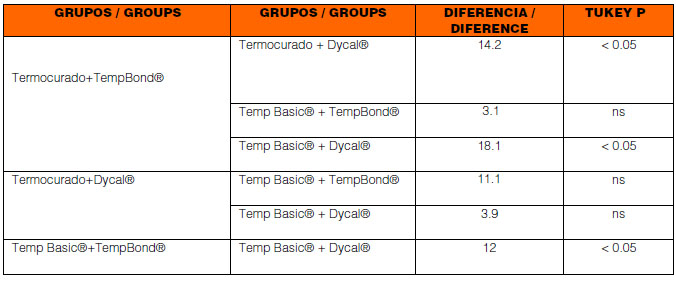

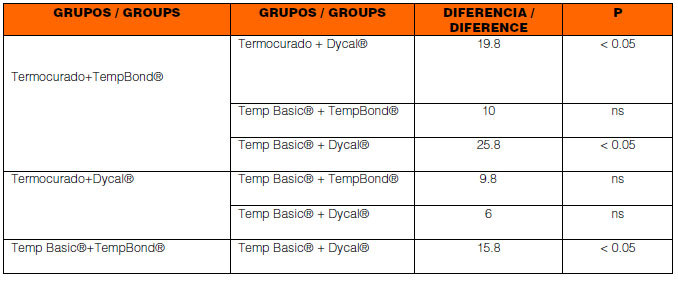

After the thermocycling procedure, the marginal adaptation of the groups was evaluated again and the means and medians of each group were established. The Kruskal-Wallis test determined that there are significant differences between the groups (P = <0.05) (table 3).

Table 3. Relationship between groups after cementation (Kruskal Wallis - Dunn). Tt: thermo-curing + tempbond; td: thermo-curing + dycal; ct: temp basic + tempbond; cd: temp basic + dycal.

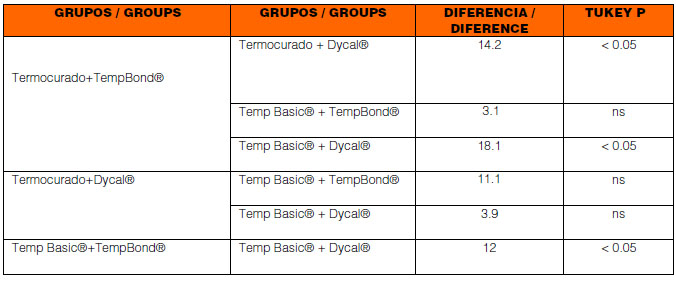

From the Kruskal-Wallis test, with a level of significance of 95% a value lower than 0.05 was obtained, the Alternative Hypothesis (Ha) was accepted, that is, there are differences with respect to the central tendency of the populations. It was compared by Dunn's method between the groups to establish similarity or difference between the groups (table 4).

Table 4. Relationship between groups after thermocycling (Kruskal Wallis - Dunn). Tt: thermo-curing + tempbond; td: thermo-curing + dycal; ct: temp basic + tempbond; cd: temp basic + dycal.

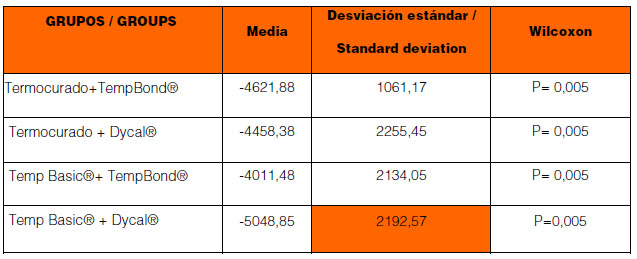

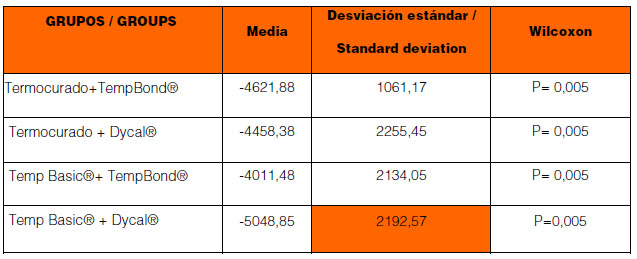

To obtain the relationship between initial data versus values after thermo cycling, Wilcoxon analysis was performed for dependent samples, there was a significant difference in all groups (table 5).

Table 5. Wilcoxon test to establish relationship between the results obtained after the cementation and after the thermocycling. (P = <0.05)

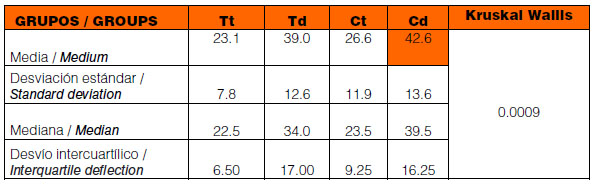

The tensile test results for each group were analyzed, establishing the means and standard deviation of each group. Kruskal Wallis determined the difference between the means of the groups (P= <0.05) (table 6).

Table 6. Mean and standard deviation of the traction test.

From the Kruskal-Wallis test, with a level of significance of 95% a value lower than 0.05 was obtained, the alternative hypothesis (Ha) is accepted, that is, there are differences regarding the tensile strength of the groups It was compared by Dunn's method between groups to establish similarity or difference between them (table 7).

Table 7. Traction resistance, comparison between groups. Tt: thermo-curing + tempbond; td: thermo-curing + dycal; ct: temp basic + tempbond; cd: temp basic + dycal.

The results determined that crowns manufactured in CAD CAM with Temp Basic® provisional resin and cemented with dycal® had the lowest microfiltration values in the two study times: after cementation and after thermocycling, and the highest tensile strength (p = <0.05). Temporary crowns cemented with TempBond® had the highest marginal discrepancy values than the other groups. In all groups the marginal discrepancy significantly increased after the thermocycling procedure (p= <0.05).

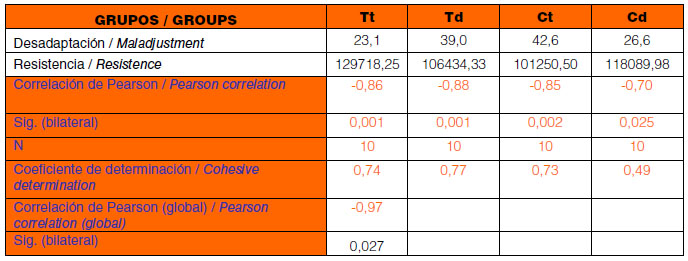

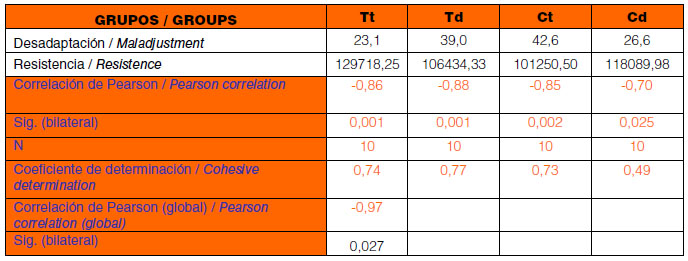

A linear correlation was made to determine if there was a relationship between marginal maladjustment and tensile strength.

Table 8. Pearson correlation between marginal discrepance and traction resistance.

Pearson's correlation coefficients (r) between maladjustment and tensile strength showed values that fluctuate between -0.7 and -0.88; The intensity of association is strong. The negative sign indicates an inverse relationship, that is, the greater the maladjustment, the lower the tensile strength. Additionally, the bilateral significance (p) is less than 0.05 in all cases, which would indicate a significant correlation of the variables.

Discusion

In the present study it was found that both provisional crowns made of Veracril® thermo-cured acrylic and those made of TempBasic® resin cemented with Dycal® exhibited statistically significant values of maladjustment than restorations cemented with TempBond®, the Temp Basic® resin group being cemented with Dycal® which presented the least marginal discrepancy. In all groups the marginal discrepancy increased after thermocycling aging. Regarding the tensile forces, it was shown that the provisional crowns cemented with Dycal® presented greater resistance than those cemented with TempBond® being the group of Temp Basic® resins cemented with Dycal® where higher retention values were evidenced.

Lee & cols., 201720, evaluated the marginal adjustment of provisional crowns manufactured with CAD / CAM milling technology and 3D printing technology. The results showed that the average discrepancy was 171.6 μm for the CAD / CAM milling group and 149.1μm and 91.1 μm for the 3D printing group. They concluded that the marginal adjustment of the provisional crowns is more prominent by the 3D printing method than by the CAD / CAM milling method.This study compared the provisional CAD / CAM cemented with dycal and presented low marginal adaptation values in relation to those cemented with NE temp bond that presented higher values, which does not match the results obtained in the present study, since the dycal provided better marginal adaptation and tensile strength in the provisional crowns manufactured with both techniques that the temp bond NE.

Likewise, Yao & cols., 201417, investigated the marginal accuracy of two Protemp 4 and Structur 2 bis-acrylic provisional materials and two CAD / CAM materials such as Teilo CAD and VITA CAD-Temp before and after thermocycling and observed in the microstereoscope, the results showed that the discrepancies in the margins were greater for the provisional crowns of acrylic bis than for the CAD / CAM crowns. However, they found no significant differences for the margin discrepancies between the provisional CAD / CAM crowns, they concluded that the provisional CAD / CAM materials presented greater marginal accuracy. In the present study, the provisional CAD / CAM cemented with dycal presented low values of marginal maladjustment in relation to those cemented with temp temp NE that presented more alterations; this could be due to the fluidity of the temporal biomaterial, which allowed it to drain more easily due to the internal surface of the crowns.

Peñate & cols., 201516, compared the marginal adjustment of provisional materials by direct technique and CAD / CAM, using different materials, Structur 3, Trim, DuraLay and Telio CAD subjected to thermocycling. The results showed marginal discrepancies over time, but no significant differences were found between the groups. In this investigation the provisional CAD / CAM cemented with dycal increased their values after thermocycleding and presented low values of marginal adaptation in relation to those cemented with temp bond NE, there were changes after thermocycling and presented higher values, so this study did not agrees with what was found by mentioned author.

Studies by Akashi & cols, 200221, evaluated the influence of four temporary cements TempBond® (Kerr), Tempbond NE (Kerr), Improv® (Sterioss) and Dycal® (Dentsply / Caulk), on marginal adaptation and tensile strength in prosthetic samples cemented in replicates of pillars CeraOne (Nobel Biocare). They concluded that the four temporary cements tested provided a similar marginal adaptation, but the Dycal® group showed greater tensile strength than those cemented with Tempbond NE®. Concordant with our study, since provisional crowns cemented with Dycal® subjected to thermocycling and tensile forces presented higher retention values compared to those cemented with TempBond NE®.

Studies by Román et al.,201722, evaluated through tensile tests the retention of five temporary cements in CAD / CAM. They used temporary cements: Dycal® (D), TempBond® (TB), TempBond® Non Eugenol® (TBNE); dual bonding cements TempBond® Clear (TBC) and Telio CS link (TE), and subjected to thermocycling and without thermocycling. The results were that the Telio CS (TE) link and TempBond® Clear (TBC) obtained the highest tensile strength values. Thermocycling reduced the strength of all cements, except TBC. This study used cements of different composition, so that dycal cement had higher retention values compared to TempBondNE cement; which is verified in the present study.

Other studies such as Fernandes & cols, 200723, coincide that dycal is the provisional cement with better tensile strength results; they evaluated the retention of temporary resin restorations cemented with four temporary cements using premolars placed in acrylic cubes, prepared for a complete crown. The provisional crowns were cemented with Temp Bond NE (Kerr), Provilink (Ivoclar), TempoCem NE (DMG) and Dycal (Densply). They concluded that Dycal obtained the best retention values, followed by Provilink and Temp Bond NE and TempoCem NE was the cement with the lowest retention. It is related to this study, since provisional crowns cemented with dycal had better marginal adaptation and tensile strength than temporary restorations cemented with TempBond NE.

Estudios de Rego & Santiago, 200424, compared the retention of cemented provisional crowns with eight temporary cements on preparations of complete crowns. The provisional crowns were cemented with Freegenol (GC), Provy New (Dentsply), Rely X Temp (3M ESPE), Temp-Bond NE (Kerr), Temp Bond (Kerr), Provicol (Voco), Nogenol (GC), Hydro -C (Dentsply). They concluded that crowns cemented with Hydro C cement were more retentive than those cemented with other cements, except Rely X Temp and Temp Bond. The least retentive crowns were cemented with temporary cements Nogenol and Freegenol. The provisional thermo-curing and CAD / CAM crowns cemented with dycal are related to the present study after being subjected to thermocycling presented higher retention values.

As in other studies, it seems clear that marginal adaptation decreases after the thermocycling process, which represents aging of the provisional restoration and loss of provisional cement; therefore, it is important to maintain an adequate retention force of the provisional restorations, since on them the pulp and periodontal integrity of the tooth depends during the manufacturing time of the definitive restoration, without proper adaptation and retention contamination could occur, Pulp problems and alteration of the contours and gingival papillae.

The difficulty to standardize the preparations has been one of the limitations of the present study, however, clinical situations of the preparation and marginal adaptation of provisional restorations are reproduced. Likewise, the human factor may influence the established parameters and protocols, but the results agree with other investigations. Within the limitations of the present study, it was possible to determine that the temporary crowns made with resin in the CAD-CAM system have a better marginal adaptation than the provisional thermo-curing crowns, however, there was no significant difference. It was also shown that the Dycal as a temporary cement it provides better retention than TempBond NE®, also allowing a better marginal adaptation of the provisional crowns.

Conclusions

Marginal microleakage is related to the cement used, provisional crowns cemented with Dycal® showed statistically lower marginal discrepancy and greater retention forces compared to TempBond NE®. The thermocycling process influenced the increase in marginal maladjustment in all groups. When the maladjustment was higher, the tensile strength decreased.

Interests conflict

The authors declare no conflict of interest in the presentation of data, preparation and publication of this article.

Acknowledgements

We thank PhD. Eduardo Garrido for the help in reviewing and correcting this article; as well as Juan Carlos Túquerres for his participation in the statistical analysis and interpretation of results.

Bibliografía

- Morgano SM, VanBlarcom CW, Ferro KJ, Bartlett DW. The history of The Glossary of Prosthodontic Terms. Journal of Prosthetic Dentistry. 2018;119(3):311-2.

- Burns DR, Beck DA, Nelson SK. A review of selected dental literature on contemporary provisional fixed prosthodontic treatment: report of the Committee on Research in Fixed Prosthodontics of the Academy of Fixed Prosthodontics. The Journal of prosthetic dentistry. 2003;90(5):474-97.

- Zortuk M, Ozdemir E, Aguloglu S. Evaluating the fracture strength of three different provisional crowns. J Int Dent Med Res. 2010;3(1):25-8.

- Patras M, Naka O, Doukoudakis S, Pissiotis A. Management of provisional restorations' deficiencies: a literature review. Journal of esthetic and restorative dentistry. 2012;24(1):26-38.

- Montero PC, López MM, Chaves SR. Análisis del nivel de éxito que se logra en el tratamiento del ajuste marginal de coronas temporales con acrílico convencional NEW STETIC® en comparación con el bys-acrílico structur Premium de Voco® en premolares inferiores. 2011.

- Dureja I, Yadav B, Malhotra P, Dabas N, Bhargava A, Pahwa R. A comparative evaluation of vertical marginal fit of provisional crowns fabricated by computer-aided design/computer-aided manufacturing technique and direct (intraoral technique) and flexural strength of the materials: An in vitro study. The Journal of Indian Prosthodontic Society. 2018;18(4):314.

- Ozcelik TB, Yilmaz B, Seker E, Shah K. Marginal Adaptation of Provisional CAD/CAM Restorations Fabricated Using Various Simulated Digital Cement Space Settings. 2018.

- Amin BM, Aras MA, Chitre V. A comparative evaluation of the marginal accuracy of crowns fabricated from four commercially available provisional materials: An in vitro study. Contemporary clinical dentistry. 2015;6(2):161.

- Givens Jr EJ, Neiva G, Yaman P, Dennison JB. Marginal adaptation and color stability of four provisional materials. Journal of prosthodontics. 2008;17(2):97-101.

- Abdullah AO, Tsitrou EA, Pollington S. Comparative in vitro evaluation of CAD/CAM vs conventional provisional crowns. Journal of Applied Oral Science. 2016;24(3):258-63.

- Renne W, Wolf B, Kessler R, McPherson K, Mennito AS. Evaluation of the marginal fit of CAD/CAM crowns fabricated using two different chairside CAD/CAM systems on preparations of varying quality. Journal of Esthetic and Restorative Dentistry. 2015;27(4):194-202.

- Mously HA, Finkelman M, Zandparsa R, Hirayama H. Marginal and internal adaptation of ceramic crown restorations fabricated with CAD/CAM technology and the heat-press technique. The Journal of prosthetic dentistry. 2014;112(2):249-56.

- Perry RD, Magnuson B. Provisional materials: key components of interim fixed restorations. Compendium of continuing education in dentistry (Jamesburg, NJ: 1995). 2012;33(1):59-60.

- Huettig F, Prutscher A, Goldammer C, Kreutzer CA, Weber H. First clinical experiences with CAD/CAM-fabricated PMMA-based fixed dental prostheses as long-term temporaries. Clinical oral investigations. 2016;20(1):161-8.

- Ehrenberg D, Weiner GI, Weiner S. Long-term effects of storage and thermal cycling on the marginal adaptation of provisional resin crowns: a pilot study. The Journal of prosthetic dentistry. 2006;95(3):230-6.

- Peñate L, Basilio J, Roig M, Mercadé M. Comparative study of interim materials for direct fixed dental prostheses and their fabrication with CAD/CAM technique. The Journal of prosthetic dentistry. 2015;114(2):248-53.

- Yao J, Li J, Wang Y, Huang H. Comparison of the flexural strength and marginal accuracy of traditional and CAD/CAM interim materials before and after thermal cycling. The Journal of prosthetic dentistry. 2014;112(3):649-57.

- Balkenhol M, Ferger P, Mautner MC, Wöstmann B. Provisional crown and fixed partial denture materials: mechanical properties and degree of conversion. Dental Materials. 2007;23(12):1574-83.

- Pegoraro LF, Valle ALd, Araujo CdRPd, Bonfante Gd, Conti PCR, Bonachela V. Prótesis fija. Prótesis fija2001.

- Lee W-S, Lee D-H, Lee K-B. Evaluation of internal fit of interim crown fabricated with CAD/CAM milling and 3D printing system. The journal of advanced prosthodontics. 2017;9(4):265-70.

- Akashi AE, Francischone CE, Tokutsune E. Effects of different types of temporary cements on the tensile strength and marginal adaptation of crowns on implants. Journal of Adhesive Dentistry. 2002;4(4).

- Román-Rodríguez J-L, Millan-Martínez D, Fons-Font A, Agustín-Panadero R, Fernández-Estevan L. Traction test of temporary dental cements. Journal of clinical and experimental dentistry. 2017;9(4):e564.

- Fernandes PFS, Vide PAFB, Almeida TC, do Amaral TD, Silva CL, Fernandes JCAS. Retencao de Cimentos Provisorios em Dentes Naturais para Próteses Fixas Unitárias. Revista Portuguesa de Estomatologia, Medicina Dentária e Cirurgia Maxilofacial. 2007;48(4):215-9.

- Rego MRdM, Santiago LC. Retention of provisional crowns cemented with eight temporary cements: comparative study. Journal of applied oral science. 2004;12(3):209-12.

Reconocimiento-NoComercial-CompartirIgual

CC BY-NC-SA

Esta licencia permite a otros entremezclar, ajustar y construir a partir de su obra con fines no comerciales, siempre y cuando le reconozcan la autorÍa y sus nuevas creaciones estÉn bajo una licencia con los mismos tÉrminos.